New Toric Carbide Endmill is Crazy Good; 5x Higher Material Removal Rate

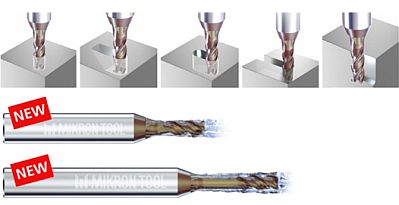

Mikron Tool has expanded the CrazyMill Cool P&S milling cutter family, developed for roughing and finishing operations, with a toric version.

The new tool combines the strengths of milling and drilling and is designed for machining stainless steel, titanium, CoCr alloys and superalloys.

Like its cylindrical predecessors, this drill/milling cutter can plunge perpendicularly into the material up to 1 x d and then continue machining laterally. It mills slots and pockets in the tightest of spaces -- with no problem at all. When a corner radius is required, it is in its element. The right tool for each shape.

It is available in the diameter range of 1 to 8 mm /.039" to .315" in the following two versions:

- Typ A: 2.5 x d CrazyMill Cool P&S Corner Radius, cutting length 2.5 x d, Z3

- Typ C: 5 x d CrazyMill Cool P&S Corner Radius, cutting length 2.0 x d, Z3

A unique tool for numerous applications: milling of holes, ramps, pockets, grooves and sides. Seemingly without resistance, the milling cutter plunges into the materials that are difficult to machine. It cuts powerfully with high precision, stability and excellent cutting parameters, even into the solid -- effortlessly.

It achieves impressive removal rates, which are possible thanks to the high cutting and feed rates and an infeed (ae) of 1 x d each. The drill milling cutter impresses with its long tool life and excellent surface quality, and this starting from a one-millimeter diameter.

Want more information? Click below.

Rate this article

View our terms of use and privacy policy ::m::